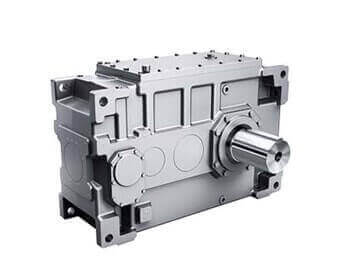

Motor & Gear is the Master Distributor for Flender Motox Gearboxes in the Southeast US and has a full line of new Flender units in stock. Flender Motox are known for maximum power in minimum space. Our geared motors support output torques of up to 20,000 Nm and higher nominal gear torques than our competitors’ geared motors of the same size. The Flender Motox units serve drive power ranges from 0.09kW to 200kW for all gear types. If you would like to know more about our flender repair services, feel free to contact us.

As a certified Flender repair business, we can carry out repairs for FLENDER standard helical and bevel-helical gear units, FLENDER REDUREX line, and FLENDER couplings. Our current repair capabilities include the following:

| Helical geared motors |

Parallel shaft geared motors |

Bevel helical geared motors |

Helical worm geared motors |

Worm geared motors |

|

| Gear designation | E38 …148; D/Z18 …188 | FZ/FD28 …188 | B28 …38 / K38 …K188 | C28 …88 | SC36 …63 |

| Typical application areas | Agitator technology Conveyor technology Cooling tower drives |

Conveyor technology Mixers Extruders |

Crane technology Airport technology Storage technology |

Theater and stage technology, waste water technology |

Conveyor technology |

| Nominal gear torque | Up to 20,000 Nm Up to 177,000 in-lbs |

Up to 20,000 Nm Up to 177,000 in-lbs |

Up to 20,000 Nm

Up to 177,000 in-lbs

|

Up to 1,590 Nm Up to 14,000 in-lbs |

Up to 166 Nm Up to 1,470 in-lbs |

| Maximum motor power (50Hz) Maximum motor power (60Hz) |

200 kW 300 HP |

200 kW 300 HP |

200 kW 300 HP |

11 kW 15 HP |

1.5 kW 2 HP |

| Number of gear sizes | 11 | 10 | 10 | 5 | 3 |

| Number of ratios | 1-/2-/3-stage | 2-/3-stage | 2-/3-stage | 2-stage | 1-stage |

| Number of ratios double gears | 4-/5-/6-stage | 4-/5-/6-stage | 5-/6-stage | 4-/5-stage | – |

| Gear ratio single-stage | 1.360 . 14.455 | – | – | – | 7 . 100 |

| Gear ratio 2/3-stage | 3.07 . 359.30 | 3.80 . 449.21 | 3.57 . 307.24 | 9.67 . 440.70 | – |

| Gear ratio double gear | 207 … 71,317 | 299 … 71,388 | 181 … 60,115 | 324 … 33,491 | – |

| Sector-specific solutions

(not available in all gear sizes)

|

Agitator variant Cooling tower variant |

Mixer variant Extruder variant |

Mixer variant Extruder variant Variant for electric monorail overhead conveyors

|

Variant for electric monorail overhead conveyors | Variant for washing bays variant for carwash |

Ask about the new F-220 / 400kW Flender Motox unit to be available in early 2011.

Motor & Gear keeps an ample inventory of Flender Gear parts on hand for quick assembly and turnaround of all standard sizes, ensuring quick turnaround. Our technicians assemble all units in our forced air clean room to minimize particle contamination of gearing and all units are 100% quality tested before delivery.

With worldwide demand for new gearbox supply at an all time high, Motor & Gear Engineering’s service of major gearbox repair is more valuable than ever to our customers. Wind energy & other new applications have many gearbox delivery cycles at 50+ weeks. Our ability to quickly & efficiently execute flender repair and other major gearboxes repair is what provides the most value to our customers; most of the time in a fraction of both the cost and the delivery cycle quoted for a new unit.

Motor & Gear Engineering has 9 gear hobs dedicated to gear manufacturing with the ability to upscale quality & new gear performance to AGMA class 10/12 with gear tooth grinding – a key component of high performance gearboxes. A full machine shop with 30 lathes, presses, shapers, planers and welding machinery make service work on shafts, splines and cases, if needed, a simple part of the repair process, with no subcontracting necessary. And with 30,000 square feet of dedicated Mechanical area for bearing & seal inventory and reassembly, your box will be back to you in working order in the most efficient time in the industry.

If you are searching for a reliable flender repair shop, feel free to contact us or request a quote at the earliest.