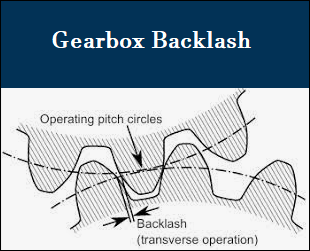

Gears are an integral part of any machine, automobile, and so on which facilitate controlled motion and speed adjustment, irrespective of the type of motion such as linear, rotational, and so on. Backlashes are essential for the smooth rotation of a gear. It offers many benefits such as facilitating lubrication. It forms a clearance and creates space between the mating teeth of the gear. This space allows for oil to lubricate the gear and prevent friction. However, this same space may mismatch the speed or cause loss of motion between input and output shafts. This poses challenges in terms of accurate positioning in machines, equipment, and so on. Hence, the gearbox backlash needs to be adjusted or even eliminated to some extent. This post discusses details on gearbox backlash adjustments.

While lubrication and space between the gear teeth is essential to some extent, this is the very reason for the backlash, primarily. So, logically, it is essential to reduce this distance. This gets the teeth in a tight mesh and helps reduce disparities or variations in terms of bearing capacities, distance between the centers of the teeth, and dimensions. There are various types of backlash and the adjustment to be done depends largely on this factor. Another important factor is reducing the tooth thickness. The tooth thickness reduction would depend on your manufacturing and machining accuracy requirements. Here are some useful pointers regarding backlash adjustment or elimination.

Are you looking for an authorized gearbox service provider for your industrial machine or automotive applications? If yes, ensure you share your requirements with the service provider in detail. Motor & Gear Engineering, Inc. is one of the leading and authorized service providers for a variety of gearbox brands. They offer repair and rebuilding services and have a market presence of more than four decades. The company offers customized solutions in automotive, hydraulics, and other related segments.